Explore the impact of magnetic separation equipment in mining and mineral processing

Magnetic separators are commonplace in most mining and mineral processing operations. However, the term ‘magnetic separator’ encompasses a diverse range of specialist separation equipment with the ability to separate widely different materials such as large tramp metal and paramagnetic minerals.

Magnetic separators for the mining and mineral processing sectors are broadly differentiated into two ranges. Firstly, magnetic separators with a deep magnetic field, such as overband magnets, are commonly used early in the process to remove tramp ferrous metal and prevent damage to crushers, screens, and conveyors.

Secondly, for mineral beneficiation, also known as ore dressing, high-intensity magnetic separators with a shallow and powerful magnetic field separate strong magnetic minerals from mined ores and quarried rocks for purification or recovery.

Early protection

Tramp ferrous metal removal occurs at the mine or quarry and at the processing plant. The process of mining and quarrying rock and ore introduces metal contamination in many forms, such as metal bars, digger teeth, nuts and bolts, and discarded metal waste. Magnetic separators separate the magnetically susceptible ferrous tramp metal and work alongside metal detectors that locate non-ferrous metal like manganese steel.

Magnetic separation equipment is required early in the process before the rock or ore is crushed and screened, reducing the risk of costly damage from tramp metal. On plants where there are several stages of crushing and screening, magnetic separators are located between the stages to remove metal liberated in the primary crusher.

Design considerations

Magnetic separator design is dictated by the plant configuration and size. Permanent and electro overband magnets are suspended over conveyors, both across and in line with the belt, with electromagnetic models used for wider conveyors transporting higher tonnages, rock, or ore.

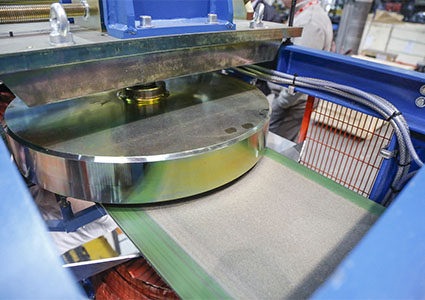

Pulley magnets are an option when the installation of an overband magnet is difficult. These replace the head pulley of the conveyor. Within ore processing applications, such as iron ore and manganese, where higher magnetic fields are required, large drum magnets with vibratory feeders are adopted.

High-intensity magnetic separators purify or concentrate non-metallic minerals and magnetic ores. The magnetic separator design is dependent on the nature of the minerals (particle size, shape, and composition, for instance) and the separation objective.

Specialized separators

For dry processing applications, mineral processors use the Rare Earth Magnetic Separator (RE Roll), the Magnetic Disc Separator (MDS), and the Induced Roll Magnetic Separator (IRS).

The IRS uses electromagnetic fields to generate high-intensity magnetic field, while RE Roll uses permanent neodymium rare earth magnets. These intense magnetic fields enable the separation of weak and para-magnetic minerals like mica or iron-coated silica, from non-metallic minerals like feldspar, silica sand, and zircon in a dry state. Once cleansed, the non-metallic minerals are used in many industries, including ceramics and glass production.

Typically, the electromagnetic MDS will feature up to three high-intensity electromagnetic discs, each set at a different from a feed conveyor. The first magnetic disc is set the furthest from the feed material, in order to extract only the mostly magnetically susceptible particles. The second and third discs are set at lower gaps, increasing the magnetic force at each disc and therefore separating different grades of magnetic material. Varying the current to each of the coils in the magnetic discs enables adjustment of the magnetic intensity to suit a specific separation objective.

Paramagnetic precision

The electromagnetic filter is adopted for removing magnetically susceptible particles from mineral slurries. The high-intensity background magnetic field (up to 10,000 Gauss) separates fine iron and paramagnetic minerals. Electromagnetic filters consist of an electromagnetic coil positioned around a central hollow core containing a magnetic (400 series) stainless steel matrix of various designs. The coil generates a high intensity magnetic field that becomes intensified on the points of the matrix creating the magnetic force needed to separate paramagnetic particles from the slurry. The process, including automated removal of the captured magnetics, is managed through a separate control panel.

As mineral resources become increasingly depleted, mining companies are turning to reserves that require more processing, which is driving an increase in demand for magnetic separators.

Paul Fears is the Press Officer at Bunting Magnetics, overseeing all media and marketing operations. Bunting is one of the world’s leading designers and manufacturers of magnetic separators, eddy current separators, metal detectors, and electrostatic separators, with globally located manufacturing facilities.