The iron evolution: adapting to market demands through innovation

The iron market is on the cusp of a significant transformation, responding to the demand for more efficient and innovative technologies, resulting in faster development at lower costs. Electrification and automation are trends sweeping many manufacturing sectors and impacting the mining industry.

How cast products are changing

Mining & Minerals Today’s readers are keenly aware of the importance of conveyors, draglines, shovels, hauling equipment, crushers, and other processing, and no doubt are witnessing a push toward more electrification and autonomous equipment and away from exclusive diesel powertrains and traditional mechanical drives systems. It’s no longer about adapting existing equipment but a call to retool and remanufacture components to align with current and future demand stemming from these power generation trends.

We’re reimagining casting designs to meet these new manufacturing needs and to fit these new operational demands. Though castings go back in history over thousands of years, castings are not static components; they are dynamic pieces of engineering art supporting an electrified future, whether housing batteries in electric vehicles or facilitating rapid development prototyping and production for drive componentry utilizing new advances via electrical or hydraulics in braking and steering mechanisms.

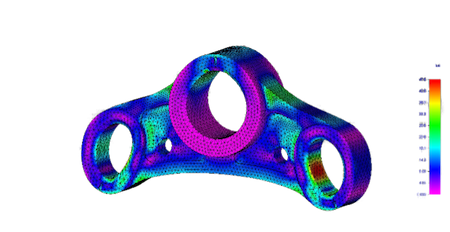

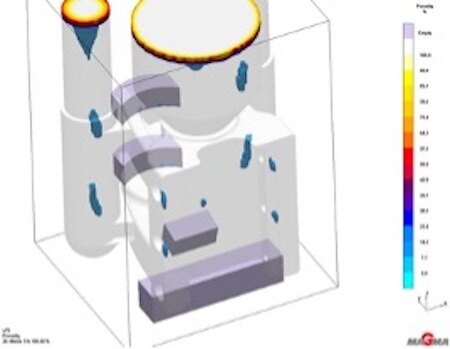

We’ve seen castings change before. Let’s take the example of draglines. In the early days, parts were designed to be very tough and heavy to account for the extreme force applied by the hoist and drag ropes. With advances in high-strength low-alloy (HSLA) steels and with more and more sophisticated simulation software, parts can be optimized in weight, thus allowing for larger buckets to be used, increasing the yd³ of material per bucket cycle. Stress analysis helps to determine the optimal geometric design, while solidification software helps to assure the production of sound castings in the foundry.

Why efficiency is required

The ‘Amazon effect’ (we’re used to getting everything we want in a day or two) propels the demand for faster processes and delivery times, compelling the mining sector to keep pace.

The crux of this modernization lies around the need for efficiency in all forms. Hydraulic fluid power is pivotal, manipulating and controlling high-pressure valves with finesse that must be balanced with the demands for new designs of electric motor housings and valve bodies. These components are not just being created; they are being conceptualized to support the transition from combustion to electricity.

While the thought of large-scale electric mining equipment was once consigned to futurism, today, it encapsulates the industry’s immediate reality. The ramifications are extensive – from the fuels we use to power machines to the methodologies by which we extract and process those very materials. Efficiency is no longer a mere aim; it is a necessity.

3D printing means faster to market and lower cost

The evolution of castings requires agility in iron and steel production supply chains. Additive manufacturing – 3D printing emerges as a beacon of innovation, offering tailored solutions and lower development costs. When prototypes can be printed using actual materials, the leap from concept to tangible product becomes startlingly swift.

It is important to note that additive manufacturing and 3D printing do not merely represent a fringe element of future mining practices – they are already here, altering the topography of the iron market’s possibilities. Printing of sand molds and cores is a common use of this technology today. Adapting to these changes will necessitate a profound understanding of the direction of the iron market, in which new technology is actively sought. This calls for the mining industry to bolster its innovation, sustainability, and efficiency.

Adaptation is not only about survival; it’s about thriving in an increasingly demanding and segmented market. With every ounce of iron extracted and each component crafted, there is a driving force of technology reshaping what it means to mine, process, and deliver the earth’s bounties.

For those willing to adapt to emerging trends and technologies, progress awaits. This is not just a revolution but an evolution of iron.

By Rick Janes and Armond Groves

Rick Janes is President at American Iron and Armond Groves, Technical and Engineering Manager at AMSCO. American Iron and AMSCO are Lawton Standard companies.

American Iron supplies continuous cast iron products to fluid power industries, bearing manufacturers, pattern shops, construction industries, and anyone requiring metallurgically superior cast iron, bronze, steel, and other alloy bars.

AMSCO® Wear Products has been providing cost-effective, wear-resistant steel since 1915. It offers innovative design, world-class quality control, and superior customer service.