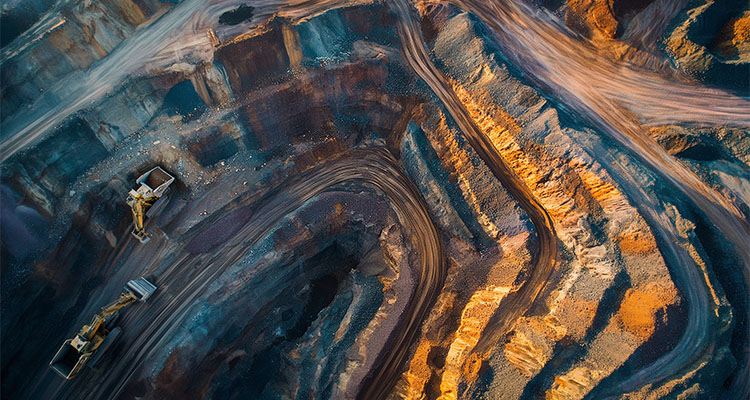

Why mining firms of all sizes need the cloud and a clean core to manage growth and meet anticipated demand for precious metals

Even for a mining and minerals industry accustomed to numbers as big as its machinery of extraction, McKinsey’s latest projections were eye-popping. By 2035, the strategy consultant expects lithium demand to jump by 475 percent, rare earths by 125 percent, nickel by 60 percent, copper by 35 percent, aluminum by 30 percent, and sulfur by 35 percent. That’s the energy transition in a nutshell, and here’s the biggest number of all: McKinsey estimates it’ll take more than $5.4 trillion in capital investment to mine enough of those and other materials to get there.

On top of all that, whether companies specialize in exploration, development, extraction, or do it all, firms large and small must also contain costs and boost efficiency, agility, and predictability. Given the pace of change, the formidable growth prospects, the surging M&A activity, and the complexities of their markets, these companies must harness technology to rationalize their systems and gain the visibility into their data and processes they’ll need to act strategically and profitably in the years ahead.

A clean core in the cloud

This is not a one-size-fits-all proposition. Global giants, exploration and development startups, and those in between have issues to address. Big companies must integrate acquisitions in high-growth resource areas and divest elsewhere, resulting in a tangle of redundant systems and massive technical debt. Smaller firms must run lean today with an eye for handling the inevitable future complexities that will come with scale. All firms need to lay the groundwork for the adoption and integration of AI as it matures and demonstrates business value in minimizing supply chain and other risks, as well as working to control costs and lift efficiency through improved visibility and automation.

Cloud-based clean-core systems (that is, based on industry standards and minimally customized) with centralized data models are a common thread in achieving these goals. Larger firms dealing with the many mergers, acquisitions, and divestitures of a fast-evolving marketplace need it to quickly integrate new arrivals and then keep tabs on the countless details of far-flung operations.

Smaller firms focusing on exploration and development, as well as those with leaner operations, may not need the comprehensive ERP systems of the big players. However, these companies need ready-to-run ERPs that systematize industry best practices across finance, inventory tracking, asset maintenance, sales, procurement, and human resources as a foundation for innovation and growth. Cloud-based ERP systems let growing mining firms build on those priorities in a modular, scalable way that can smoothly accommodate future growth and business-line expansion.

Asset intelligence and analytics as differentiators

The lion’s share of that $5.4 trillion in estimated decadal mining investment will be in assets. Cloud-based, modular core ERP systems make a huge difference in maximizing the value a mining company derives from its asset base. Where exactly are the assets? What’s their availability, utilization, and maintenance status? What tends to break, and what’s the inventory status of replacement parts if it does?

Analytics are one of the biggest value drivers of centralizing data in cloud-based systems, whether those analytics are rules-based or AI driven. GenAI’s ability to distill data from diverse sources shows great promise in areas such as supply chain risk management. GenAI can take factors like price volatility, comparative costs, local political conditions, geopolitical concerns, transit risks, and natural disaster risks into account and enable fast-paced scenario planning that serves as an early warning system for the business. The outputs help planners balance inventory levels and locations with the risks of supply chain disruption. Importantly, GenAI systems let business managers run scenarios based on natural-language queries, so they don’t have to wait for data scientists to set up and run custom queries.

Satisfying stricter regulatory requirements

Supply chain traceability is another emerging mining business requirement. Regulators around the world, but particularly in Europe, are demanding emissions accountability down the supply chain. Mining firms selling to directly or indirectly to battery manufacturers, auto companies, and others must have systems in place to track and account for the carbon emissions and critical minerals associated with their products and operations, as well as with their own supply chains. With mining, the required reporting extends to other environmental and labor elements. It’s hard to report or act on what you’re not tracking and given the geographic and product-level diversification afoot in mining, ERP systems will be increasingly vital in accurately following it all.

The list of benefits from an AI and analytics friendly, cloud-based clean core is long and growing. Workforce-related intelligence and automated procurement that lets buyers focus on more complex purchasing are just further two examples. But you get the larger point: whether you’re a global giant or a niche player with ambitious plans, getting your IT systems right will play a decisive role in a mining company’s success in this high-growth, radically evolving market.

For a list of sources used in this article, please contact the editor.

Stefan Weisenberger has worked at SAP for over 20 years, and currently occupies the role of Global Vice President for Process Industries and Natural Resources. With more than 25 years of experience in IT and metals manufacturing, Vimal Gaba is SAP’s Global Head for the Mining & Metals Industry Business Unit (IBU).